Screw Flights

Established in the year 2020, Trivella Conveyors is a joint venture of two manufacturing MGMT Tools & Hardware PVT. LTD. (Leading Manufacturer of Tool box, Tool Trolley, Industrial Trolley, Vibration Motor & Agro Process machinery Spares,) based in Sidhpur, Gujarat State of INDIA. and Makwel Industries (Leading Manufacturer of Agriculture Implement under the Brand name of SAMRAT ) based in Gujarat State of INDIA.

Trivella Begins its journey with an Idea of Mr. M B Unjhawala's to provide expertise in screw augers and screw segments which are widely used in industrial sectors such as Agro Processing, Pharmaceuticals, Construction, Mining, Metal Industries, Minerals as well as chemical Industries. Their utility comes handy especially at cement plants, sewage treatment plant, sand washing and mineral plants as well.

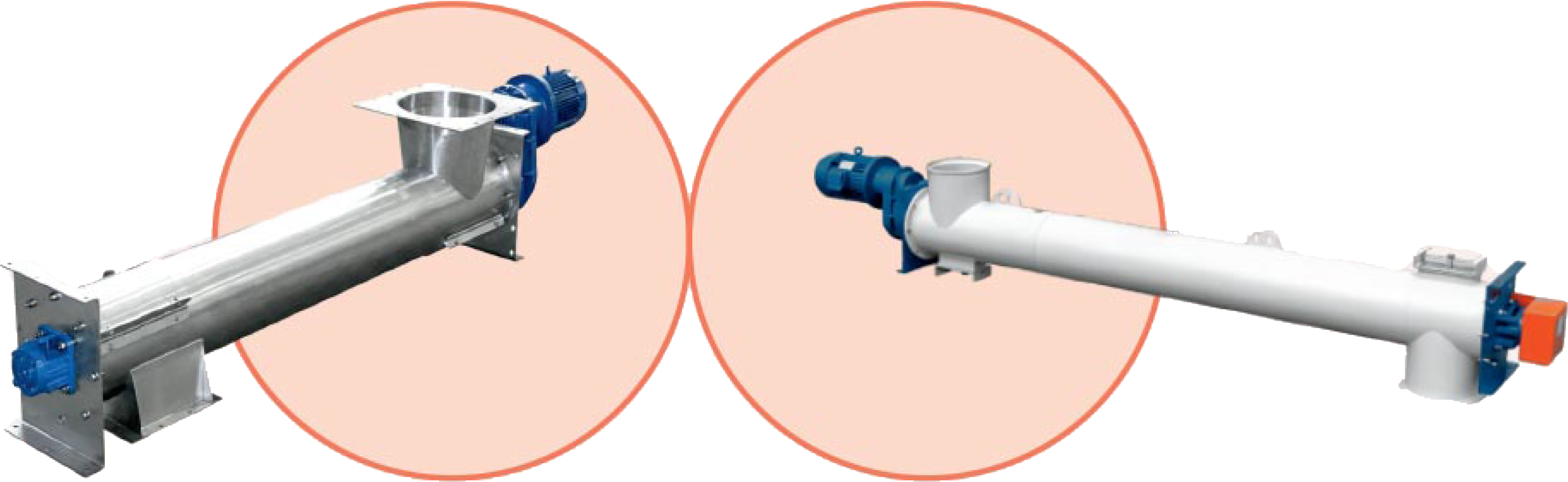

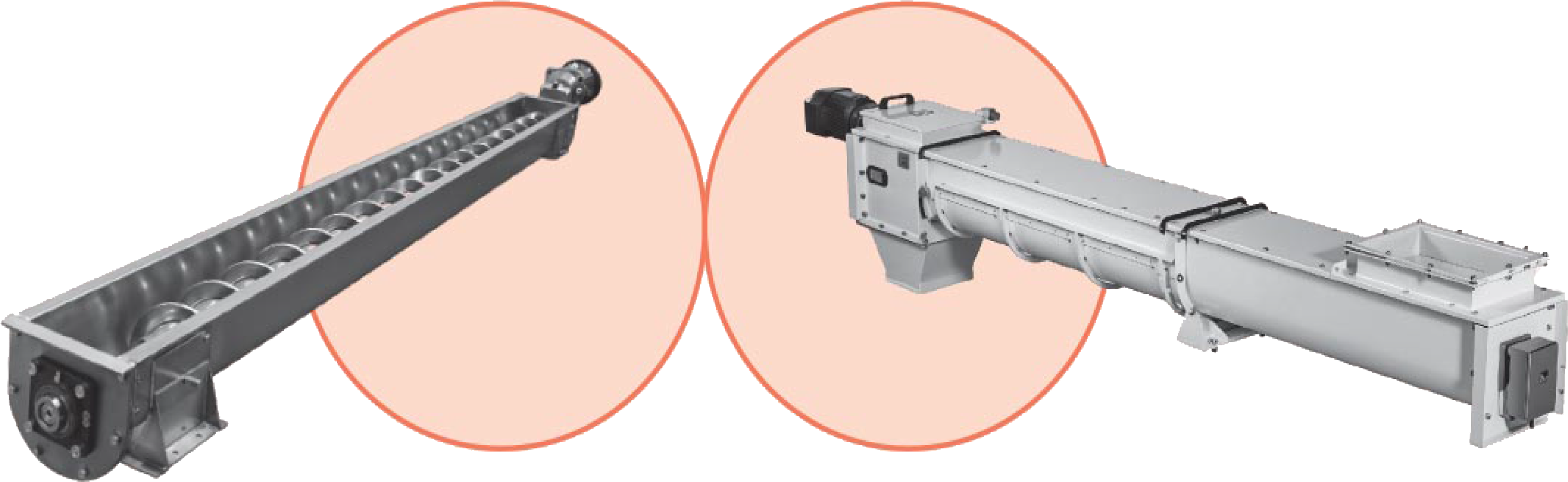

Tubular Screw Conveyors

A Tubular Type Screw Conveyor is a fully enclosed conveyor used to transport powders and granular materials horizontally or at an incline. The screw rotates inside a circular tube, preventing material spillage and dust emission. It is ideal for hygienic, dust-free handling in agro, food, chemical, and industrial applications.

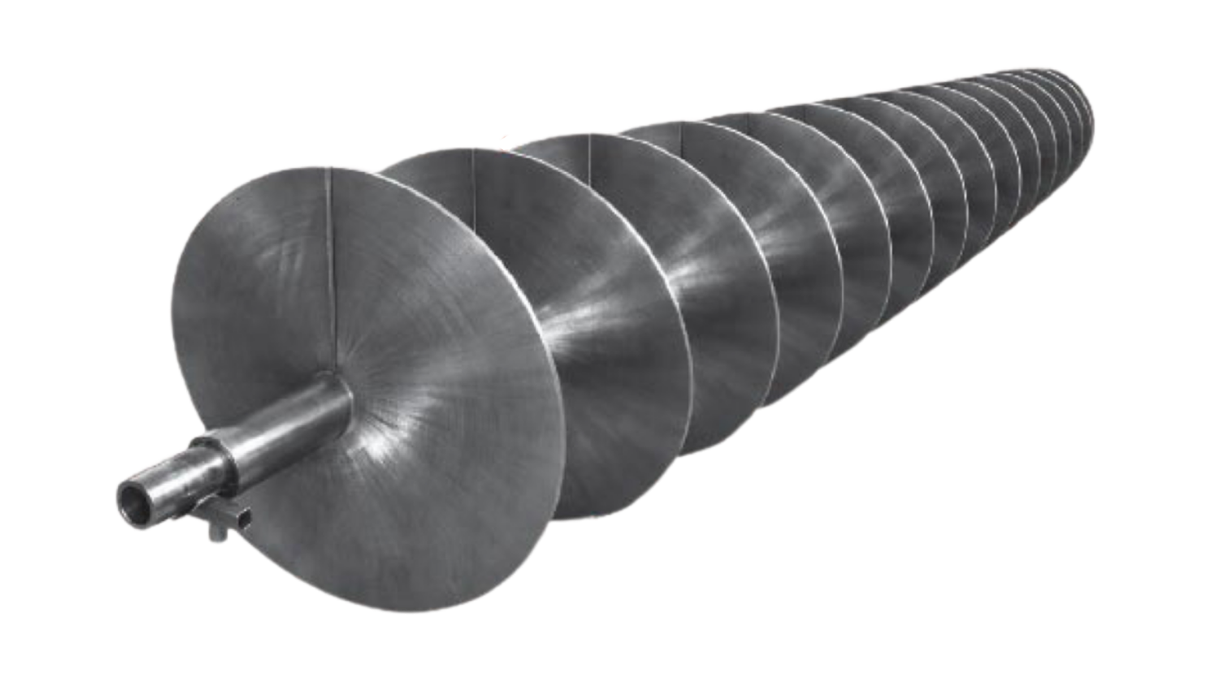

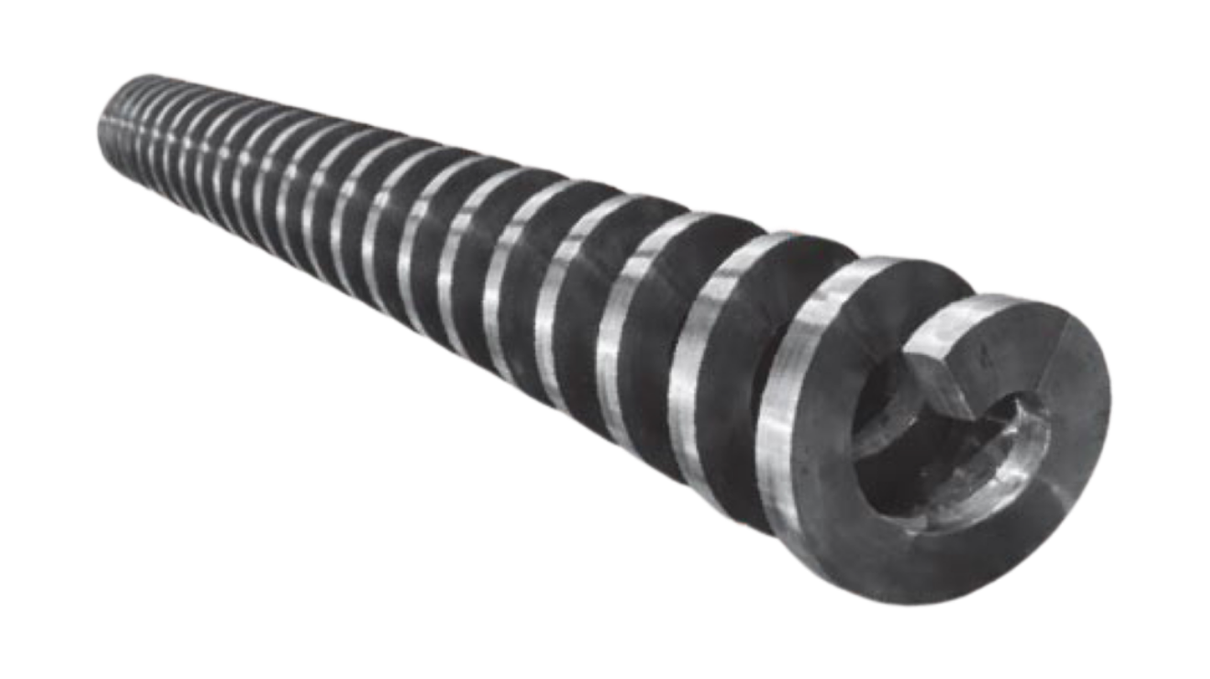

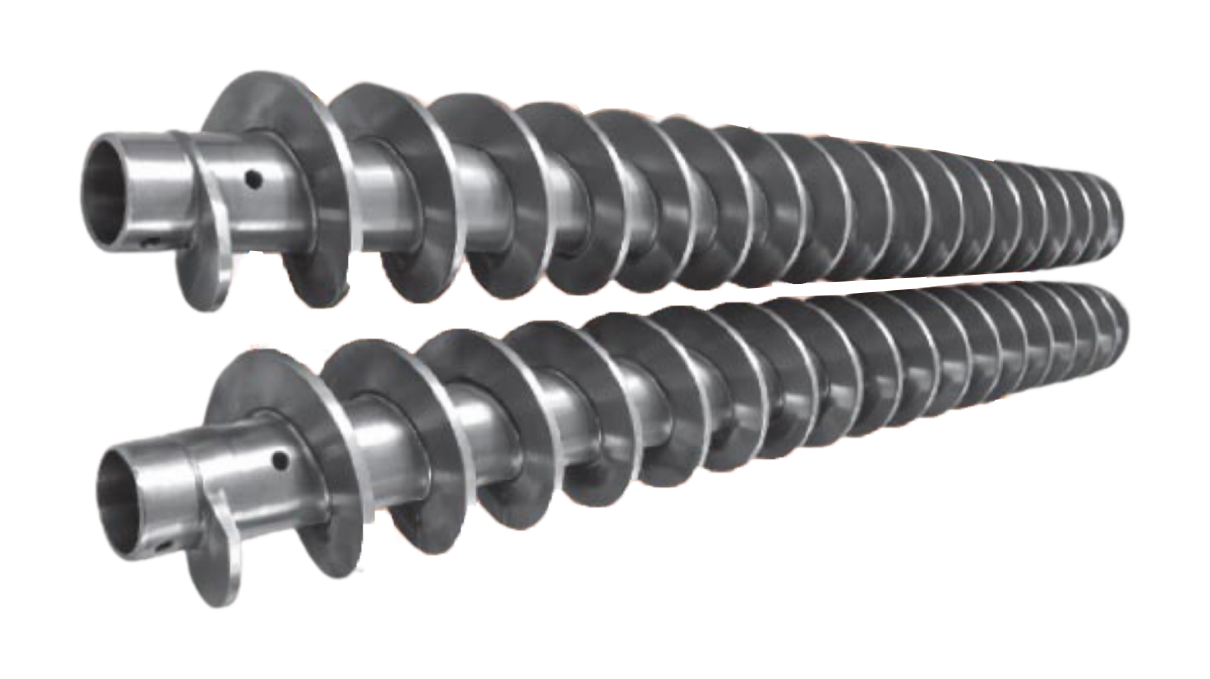

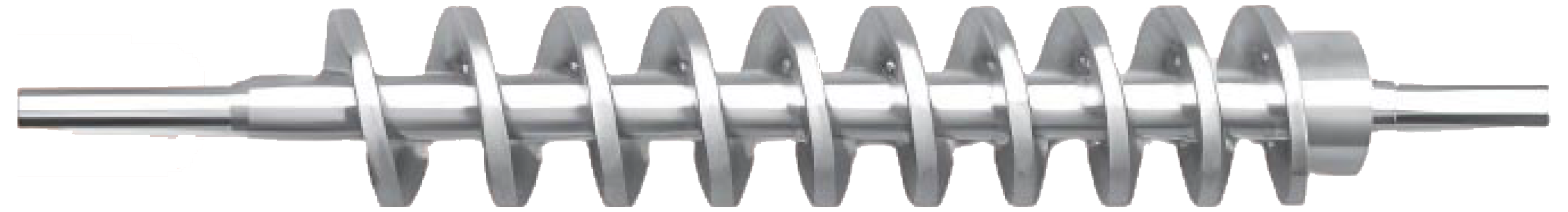

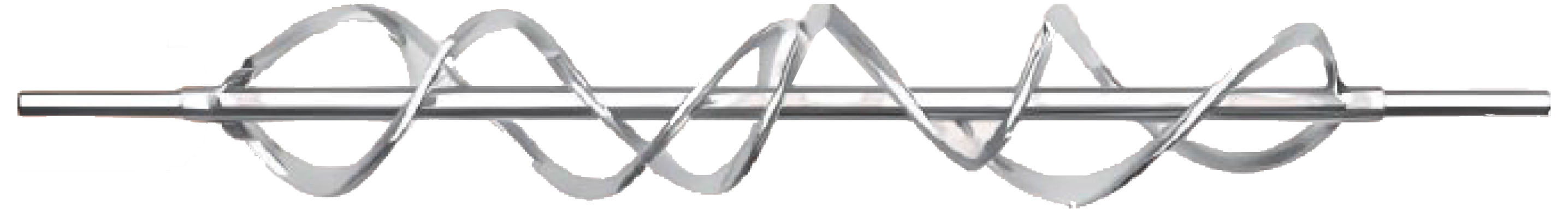

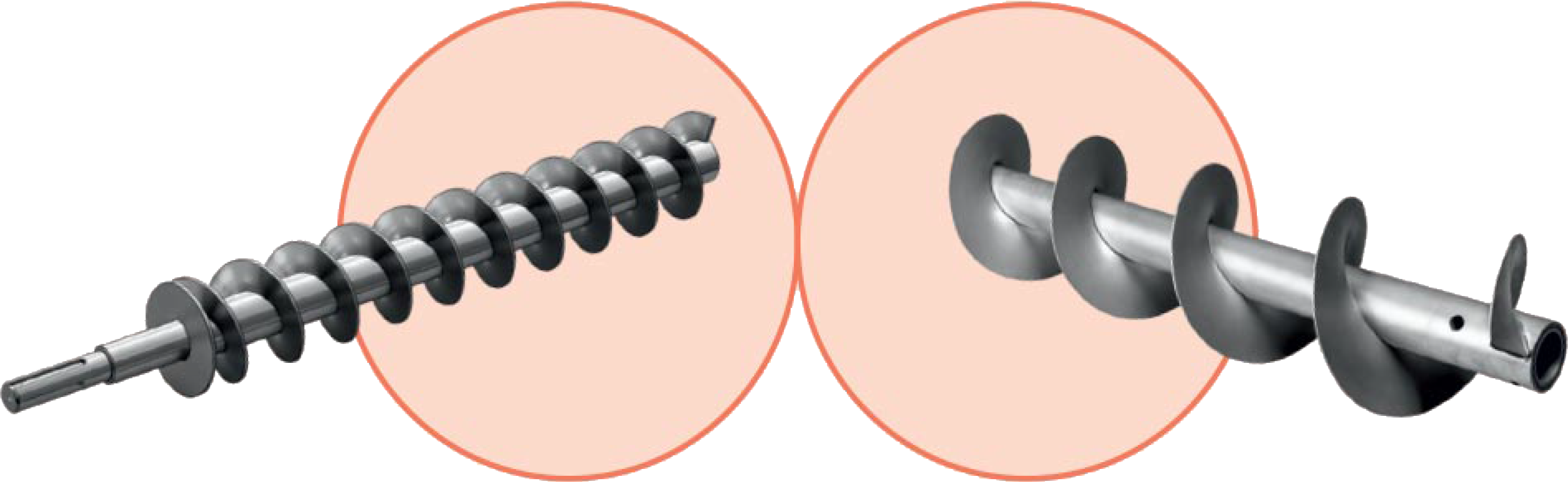

Screw Conveyor Shafts

A Screw Conveyor Shaft consists of screw flights permanently welded to a central shaft, forming a rigid single-piece assembly. This design ensures high strength, accurate alignment, and reliable torque transmission. It is commonly used for handling heavyduty, abrasive, or high-capacity materials in industrial applications.

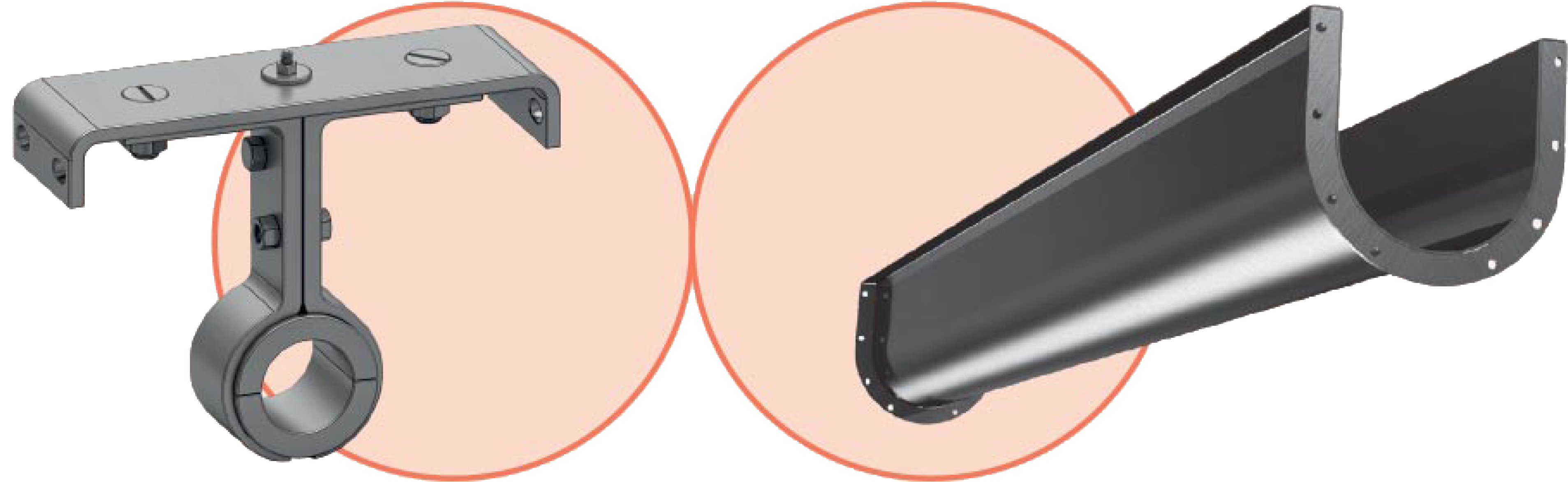

Screw Conveyor Accessories

A Tubular Type Screw Conveyor is a fully enclosed conveyor used to transport powders and granular materials horizontally or at an incline. The screw rotates inside a circular tube, preventing material spillage and dust emission. It is ideal for hygienic, dust-free handling in agro, food, chemical, and industrial applications.

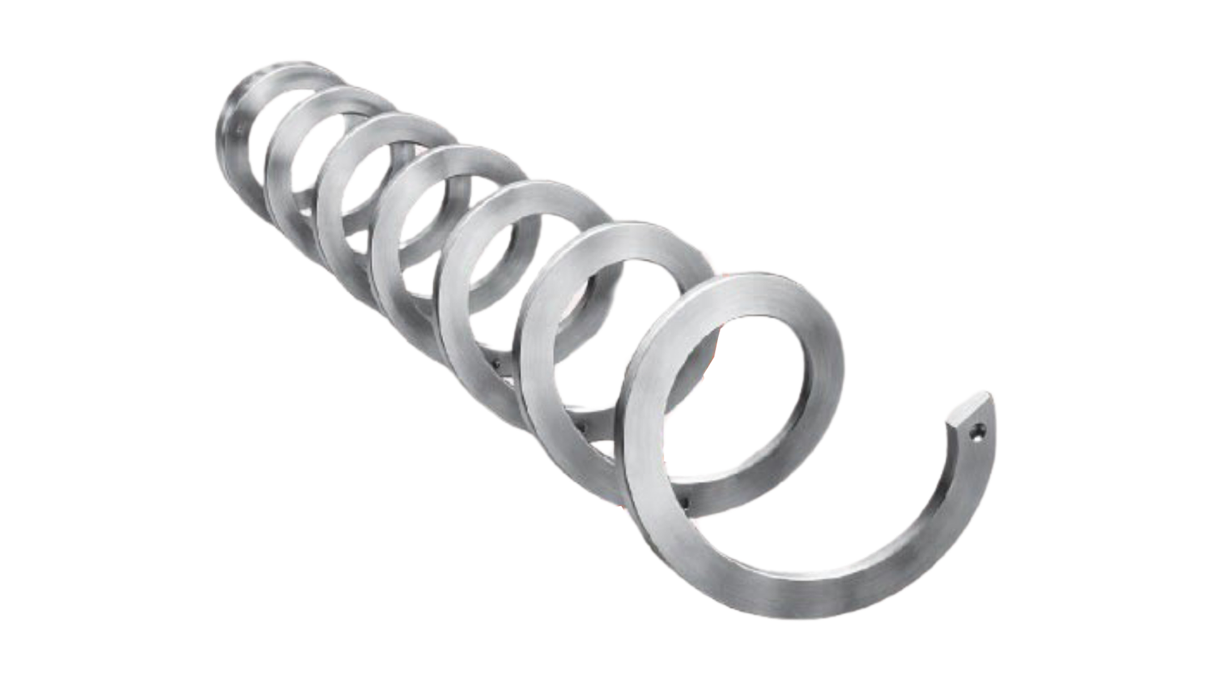

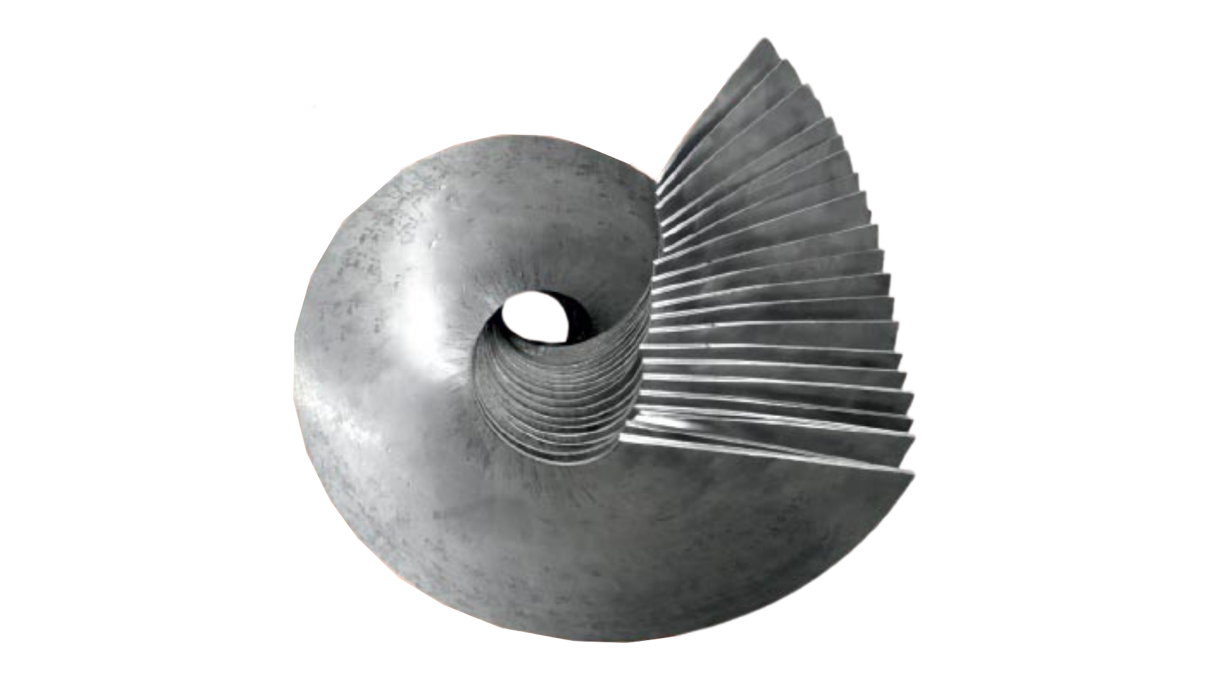

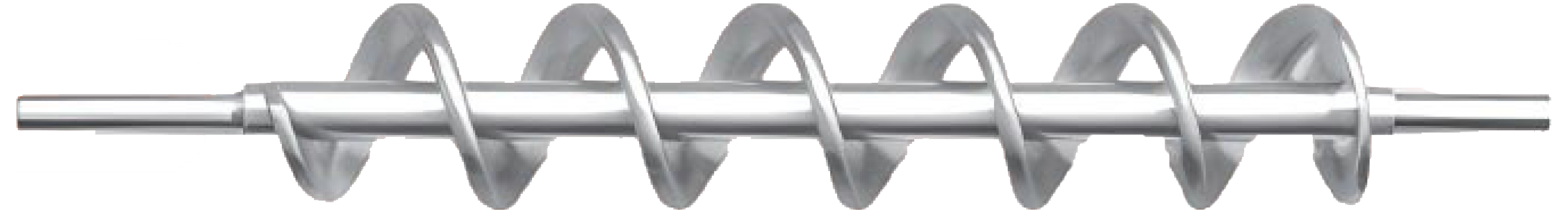

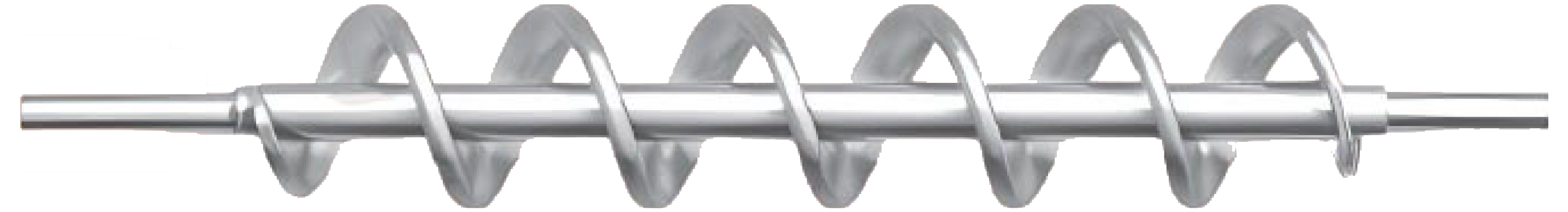

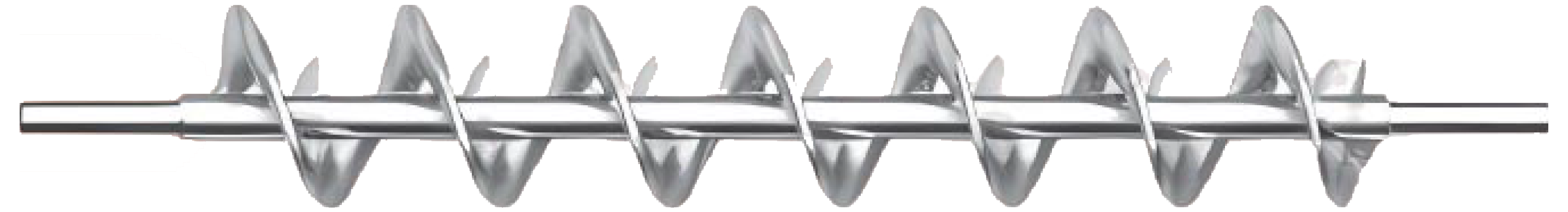

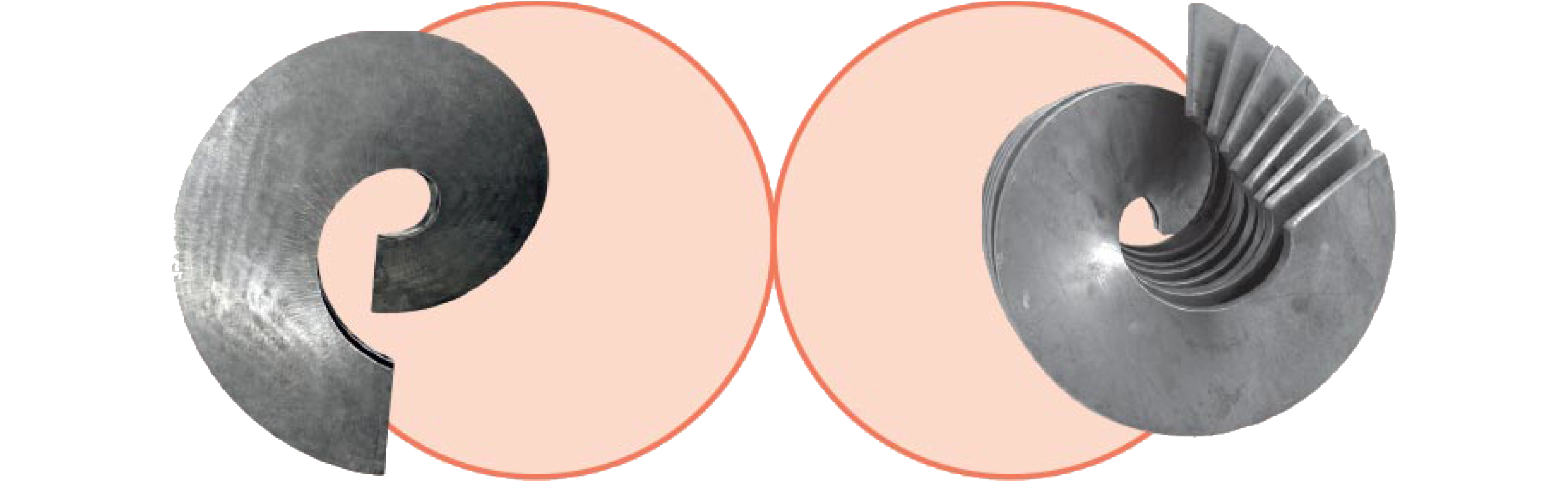

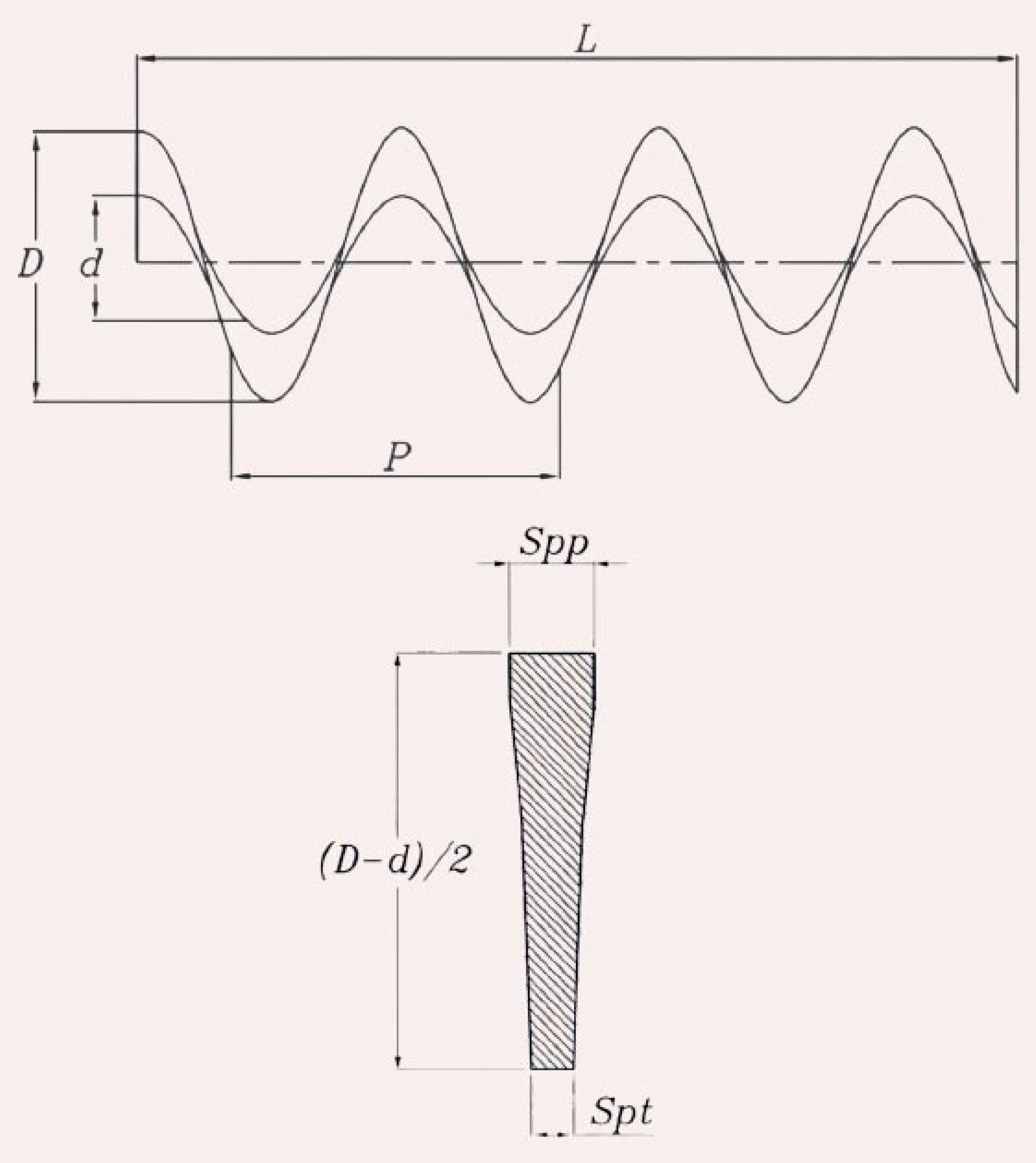

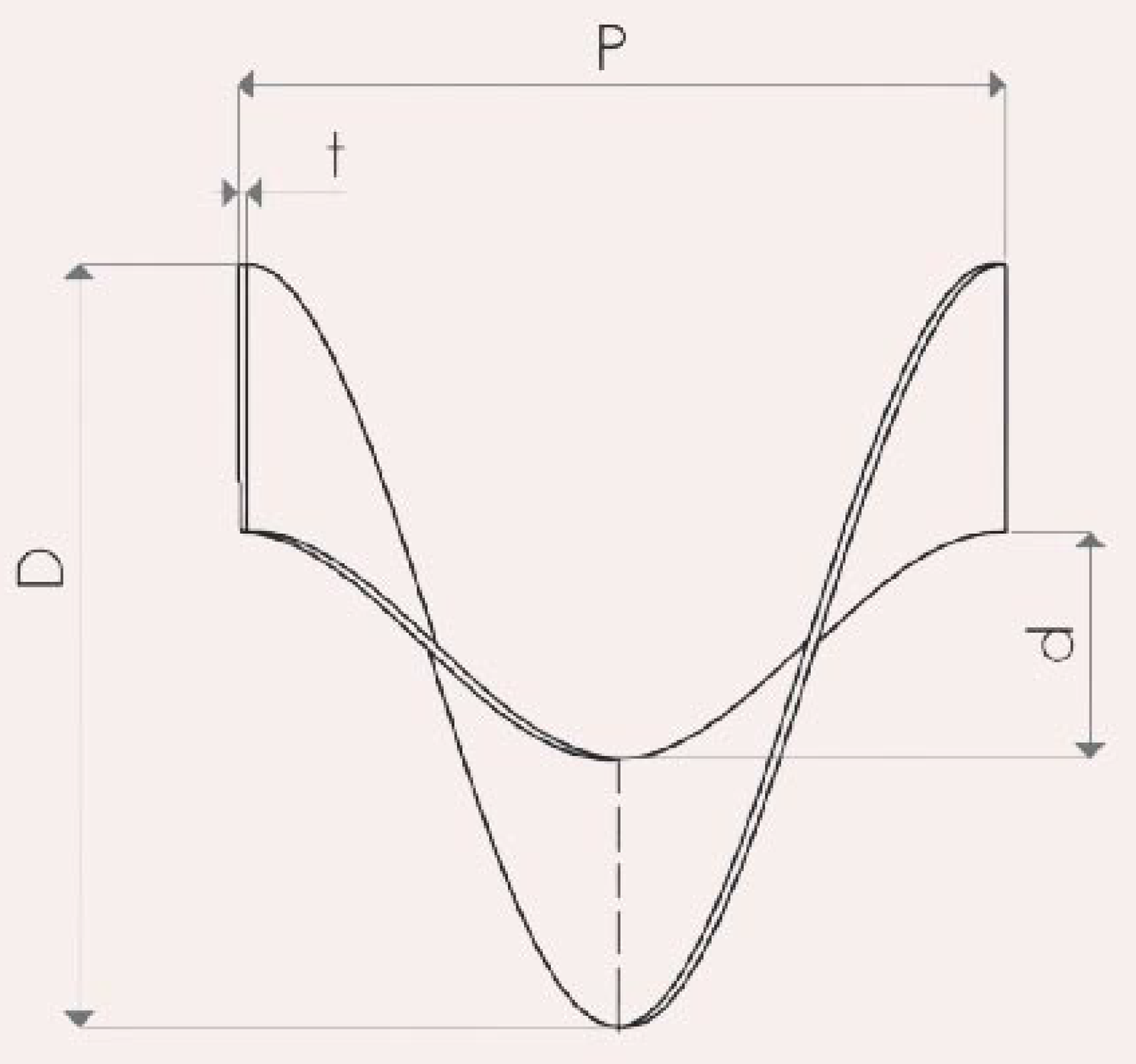

Continuous Screw Flight

Continuous screw conveyor flights are spiral blades mounted on a central shaft to move bulk materials like powders, grains, and chemicals horizontally or on an incline. Their size, pitch, and material (such as carbon steel or stainless steel) are selected based on the material handled and required capacity.

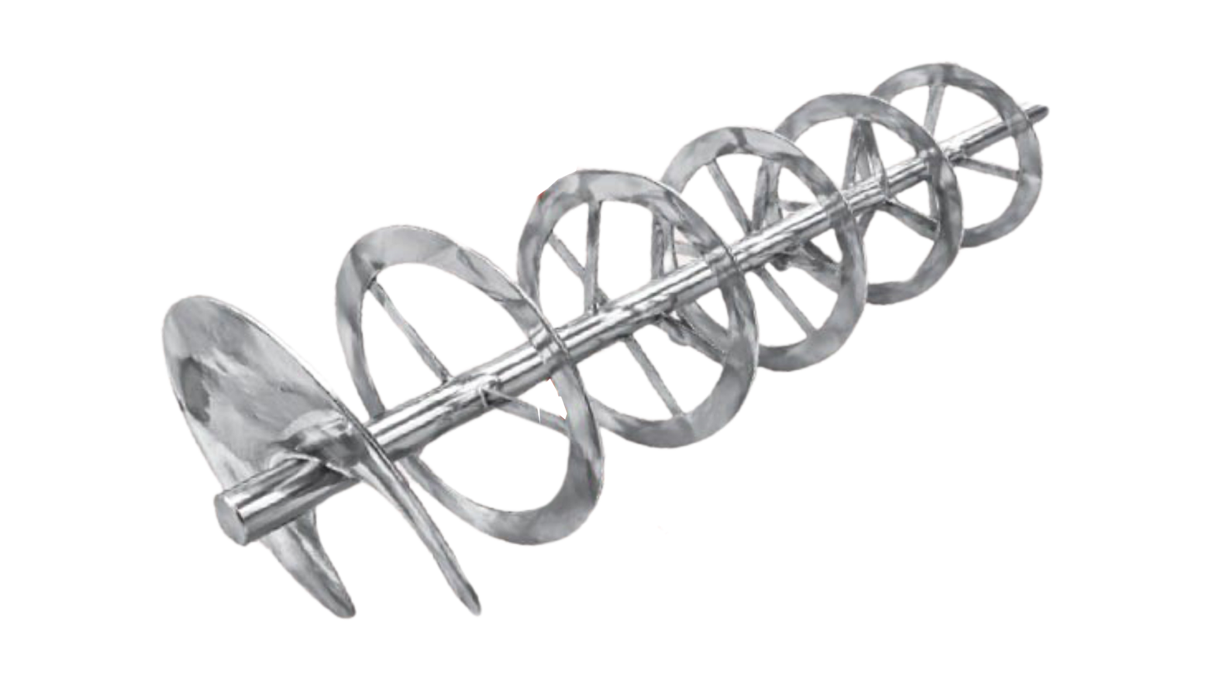

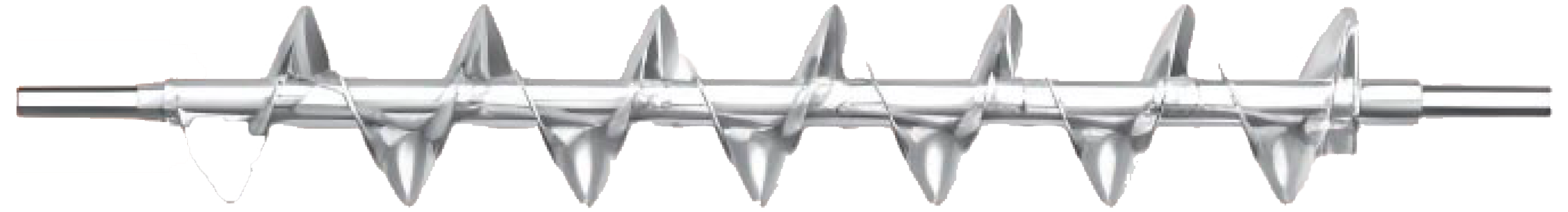

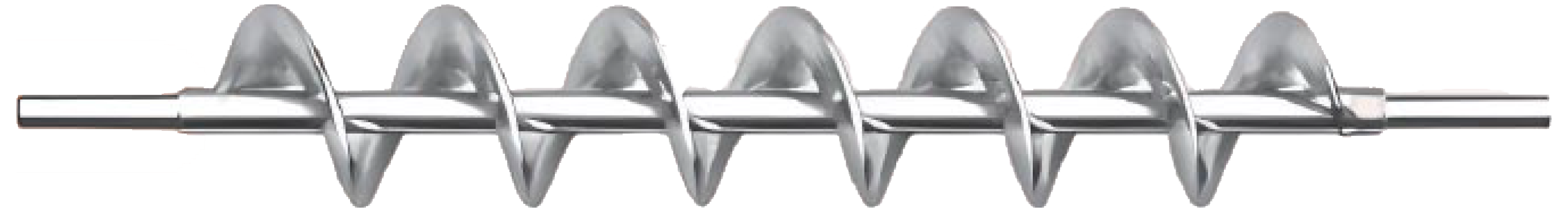

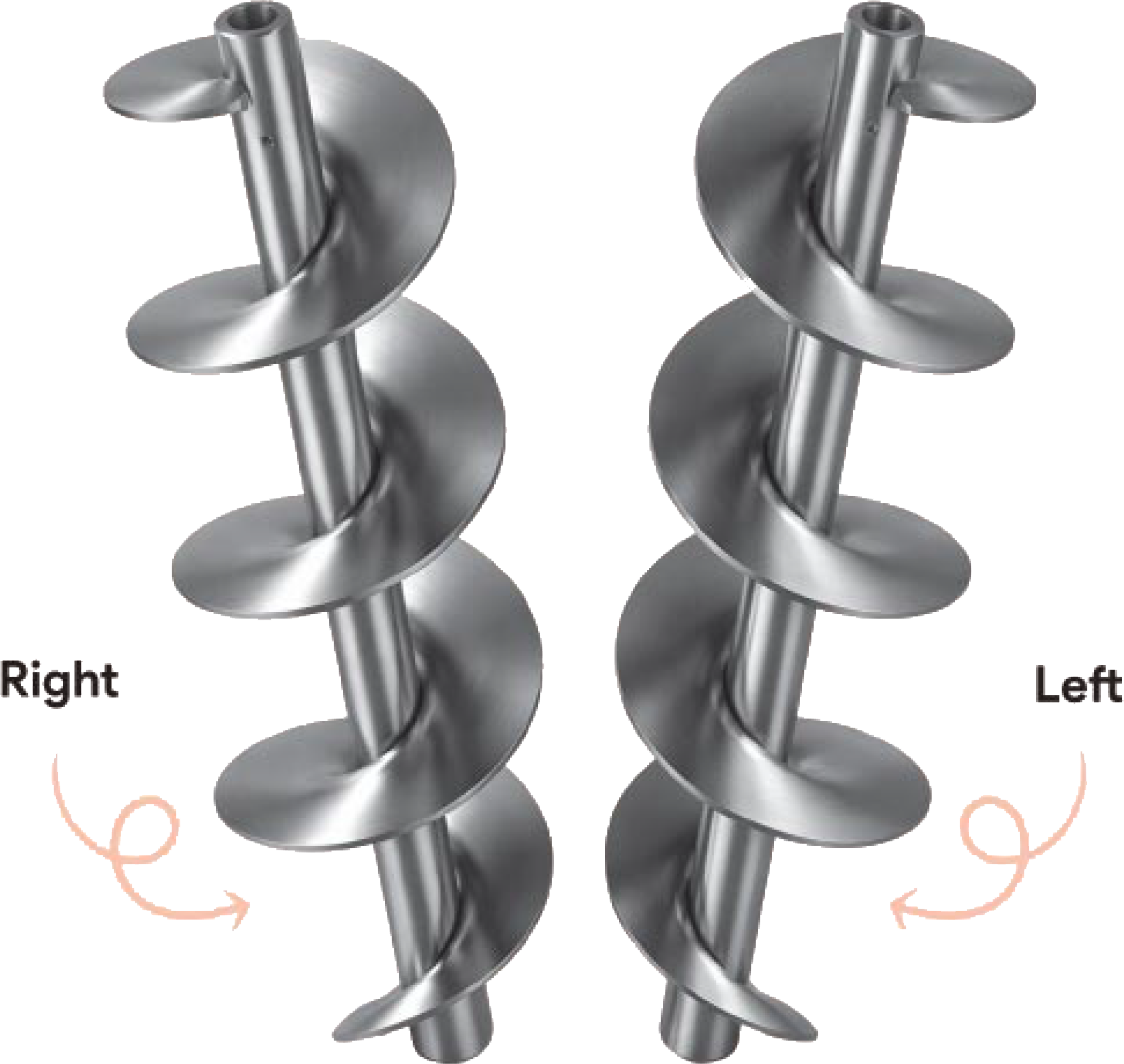

Segmented Screw Flight

A screw segment is a single piece of screw flight with a helical shape, used in machines like conveyors and extruders to move materials along a fixed path. Mounted inside a tube or housing, it rotates to transport material and is made in various sizes and designs, typically from metal, for strength and durability across industries.

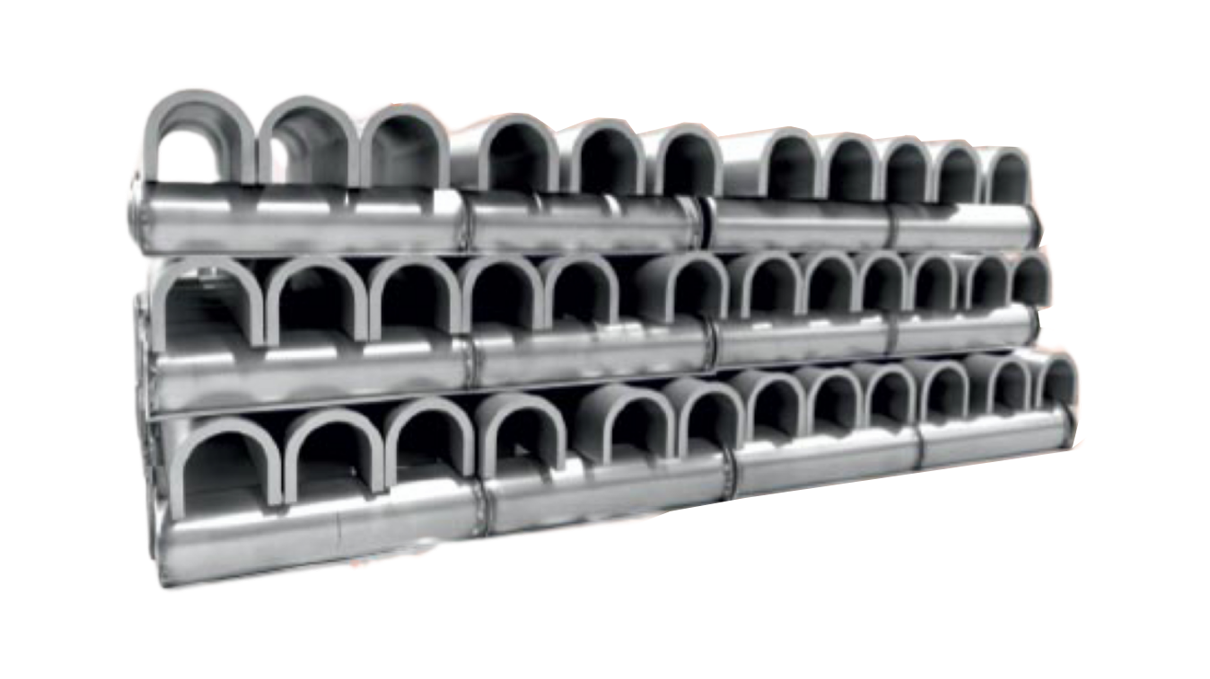

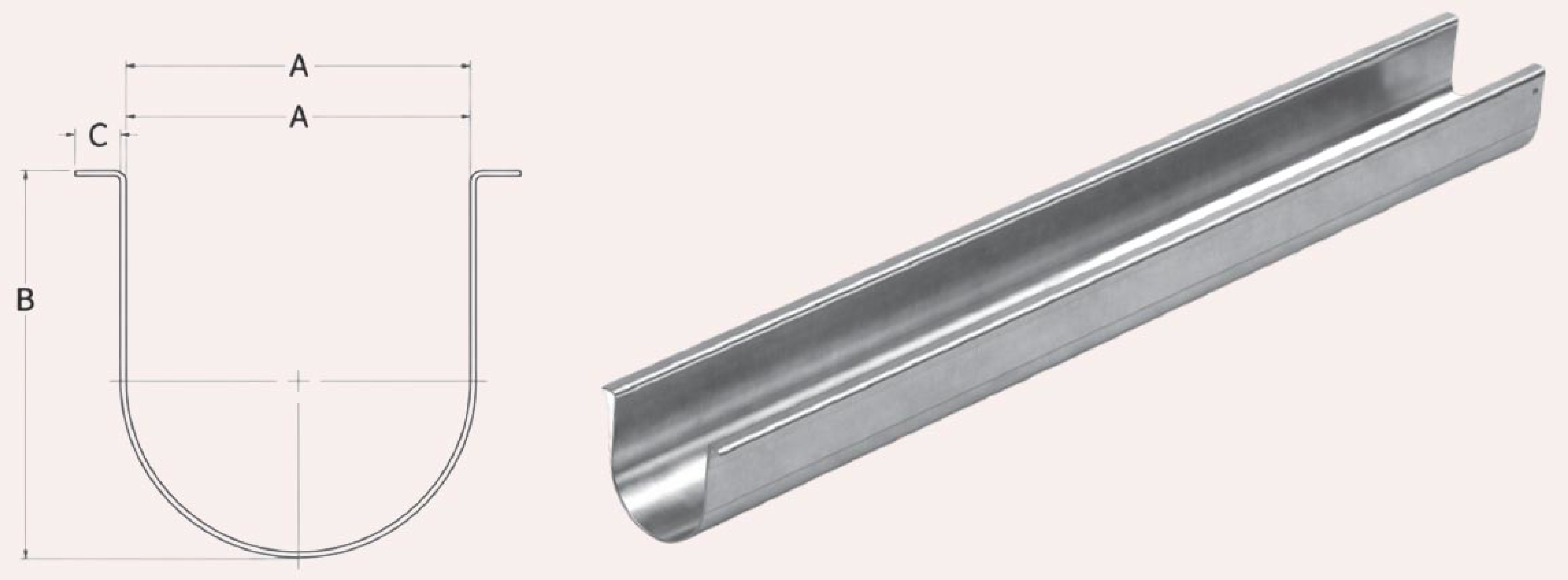

U-Through Screw Conveyor

A U Trough Type Screw Conveyor is a bulk material handling device used to convey powders, granules, and semi-solid materials horizontally or at a slight incline. It consists of a rotating screw mounted inside a U-shaped trough, allowing easy inspection, cleaning, and maintenance. It is widely used in agro, food, chemical, and industrial applications for efficient and controlled material transfer

Available Sizes

| MS CONTINOUS SCREW FLIGHT SIZE CHART | |||||

|---|---|---|---|---|---|

| No. | TYPE | OD | ID | PITCH | THICKNESS |

| 1 | RIGHT / LEFT | 70 | 33 | 70 | 3-4 |

| 2 | RIGHT / LEFT | 100 | 33 | 100 | 3-4 |

| 3 | RIGHT / LEFT | 125 | 42 | 125 | 3-4 |

| 4 | RIGHT / LEFT | 150 | 42 | 150 | 4-5 |

| 5 | RIGHT / LEFT | 175 | 42 | 175 | 4-5 |

| 6 | RIGHT / LEFT | 200 | 48-60 | 200 | 4-5 |

| 7 | RIGHT / LEFT | 250 | 60-76 | 250 | 4-5 |

| 8 | RIGHT / LEFT | 300 | 76 | 300 | 5 |

| 9 | RIGHT / LEFT | 320 | 89 | 320 | 5 |

| 10 | RIGHT / LEFT | 350 | 114 | 350 | 5 |

| 11 | RIGHT / LEFT | 400 | 114 | 400 | 5 |

| 12 | RIGHT / LEFT | 450 | 141 | 450 | 5 |

| 13 | RIGHT / LEFT | 500 | 141 | 500 | 5 |

| SS CONTINOUS SCREW FLIGHT SIZE CHART | |||||

|---|---|---|---|---|---|

| No. | TYPE | OD | ID | PITCH | THICKNESS |

| 1 | RIGHT / LEFT | 70 | 33 | 70 | 3 |

| 2 | RIGHT / LEFT | 90 | 33 | 90 | 4 |

| 3 | RIGHT / LEFT | 100 | 42 | 100 | 4 |

| 4 | RIGHT / LEFT | 125 | 42 | 125 | 4 |

| 5 | RIGHT / LEFT | 150 | 42 | 150 | 4 |

| 6 | RIGHT / LEFT | 175 | 42 | 175 | 4 |

| 7 | RIGHT / LEFT | 190 | 60 | 190 | 4 |

| 8 | RIGHT / LEFT | 200 | 48-60 | 200 | 4 |

| 9 | RIGHT / LEFT | 240 | 76 | 240 | 4 |

| 10 | RIGHT / LEFT | 250 | 76 | 250 | 4 |

| 11 | RIGHT / LEFT | 300 | 76 | 300 | 4 |

| SCREW SEGMENT / AUGER | |||||

|---|---|---|---|---|---|

| PARTICULAR | OD | ID | PITCH | THICKNESS | TYPE |

| Minium | 50 | 20 | 50 | 3 | RIGHT / LEFT |

| Maximum | 1800 | 1200 | 1200 | 40 | RIGHT / LEFT |

| MATERIAL OF CONSTRUCTION(MOC) | |||||

|---|---|---|---|---|---|

| Mild Steel (MS) | Stainless Steel (SS) 410 | ||||

| Stainless Steel (SS) 202 | Stainless Steel (SS) 310 | ||||

| Stainless Steel (SS) 304/304L | MS Carbon Steel | ||||

| Stainless Steel (SS) 316/316L | Hardox | ||||

| U TROUGH SIZE CHART | |||||||

|---|---|---|---|---|---|---|---|

| MODEL | HELICAL DIAMETER (MM) | TROUGH LENGTH (MM) | THICKNESS (MM) | A (MM) | B (MM) | C (MM) | D (MM) |

| TC-150 | 150 | 2440 | 2 | 180 | 120 | 30 | 240 |

| TC-175 | 175 | 2440 | 2 | 205 | 150 | 30 | 265 |

| TC-200 | 200 | 2440 | 2/2.5/3 | 230 | 150 | 40 | 310 |

| TC-250 | 250 | 2440 | 2/2.5/3 | 280 | 225 | 40 | 360 |

| TC-300 | 300 | 2440 | 3/4 | 330 | 250 | 40 | 410 |

| TC-350 | 350 | 2440 | 3/4 | 380 | 250 | 60 | 500 |

| TC-400 | 400 | 2440 | 4/5 | 440 | 275 | 60 | 560 |

| TC-450 | 450 | 2440 | 4/5 | 490 | 300 | 60 | 610 |

| TC-500 | 500 | 2440 | 4/5 | 540 | 325 | 60 | 660 |

| TC-550 | 550 | 2440 | 4/5/6/8 | 590 | 375 | 60 | 710 |

| TC-600 | 600 | 2440 | 4/5/6/8 | 640 | 400 | 60 | 760 |

Capability to you Handle Special & Challenging Materials

Powdered Milk

Copper Sulfate

Drilling Sludge

Ammonium Sulfate

Bread Crumbs

Silica Gel

Hay

Quartz

Almonds

Grass

Rice Grits

Wood Bark

Product Highlights